INDUCTION TO CEMEX FALCON

Cemex Falcon L.L.C. operates a Fly Ash, Slag and cement grinding mill located in Jebel Ali Industrial 3, Dubai, U.A.E., the plant has a capacity of 1.6 million tons per year, and has three main products: Fly ash, ground granulated blastfurnace slag (GGBS) and Portland cement.

The Material of fly ash which is exclusively imported from Hassyan Clean Coal Power Complex is the first (non-captive) coal-fired thermal power plant in the Middle East. It consists of 4 units X 600 MW each = Total 2400 MW with ultra-supercritical technology and low heat rate. It is one of the most advanced and sophisticated coal-fired thermal power plants in the world.

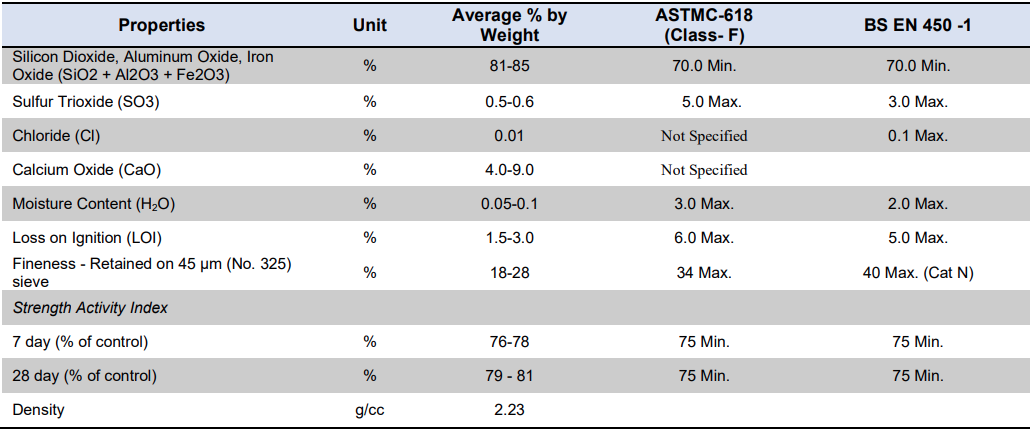

The finished product is rigorously tested in Cemex’s quality control laboratory. Cemex Falcon fly ash complies with the requirements of ASTM C618 & BS EN 450 -1

Fly ash is an extremely fine powder consisting of spherical particles less than 50 microns in size. Fly ash is one of the construction industry’s most used pozzolans. Pozzolans are siliceous or siliceous/alumina materials possessing the ability to form cementitious compounds when mixed with lime (calcium hydroxide, or Ca(OH)2) and water . When Portland or Portland limestone cement is mixed with water, most of the cement forms insoluble Calcium-Silicate-Hydrate (C-S-H) gel; Calcium Hydroxide – Ca(OH)2 is also formed as part of this reaction. When fly ash is introduced into concrete, it reacts with the Ca(OH)2 to form additional C-S-H gel..

Fly ash also can be used to improve concrete workability, decrease permeability, reduce sulfate attack, decrease bleeding and segregation, reduce shrinkage, reduce heat of hydration, increase compressive strength, and increase flexural strength. Fly ash is suitable for a variety of concrete construction applications from general construction to dams, piers, massive mat placements, footings and similar structures

The three test methods for Fly Ash are fineness, loss on ignition (LOI) and chemical composition. These are complying to ASTM C618.

Fineness: Fineness measured by determining the wet sieve residue on a 45-micron sieve.

Loss on Ignition (LOI): Loss on ignition provides an indication of the unburnt carbon (coal) present in the Ash

Chemical Composition: of Fly Ash is dependent upon the coal being fired. The chemistry of an ash affects its performance

SPECIFICATION

APPLICATION

• Pre-mixed concrete.

• Stabilized road base.

• Roller compacted concrete pavements.

• Concrete sub-base.

• Conventional concrete pavements.

• Roller constructed concrete dams.

• Concrete products.

MIX DESIGN

Proposed mix designs using Fly Ash should be evaluated for performance prior to commencing production. By fine tuning, concrete characteristics can be optimized to achieve desired performance.

HANDLING, STORAGE & SAFETY

Fly Ash may contain crystalline silica and should be used and handled appropriately – refer to the Safety Data Sheet.

Fly Ash should be stored in a dry environment off the ground.

FEATURES

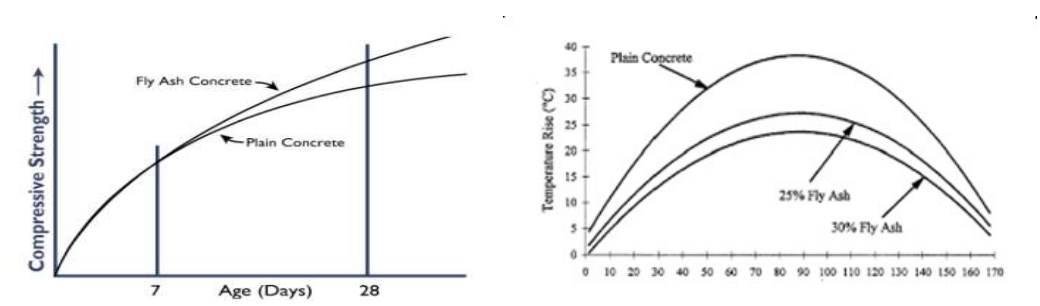

Later Age compressive strength:

A fly ash concrete mix, designed for equivalent performance to conventional concrete at normal ages, will generally gain strength more slowly at early ages. After about seven days, the rate of strength gain of fly ash concrete exceeds that of conventional concrete, enabling equivalence at the desired age. This higher rate of strength gain continues over time, enabling fly ash concrete to produce significantly higher ultimate strength than can be achieved with conventional concrete.

Reduction in Heat of hydration

Heat is the result of the hydration reaction between the cement and water, so a higher content of cement results in a higher heat of hydration. The replacement of cement by fly ash typically decreases the heat evolution due to a slower hydration reaction

Better workability

Cohesiveness

Resistance to chemical attack

Resistance to chloride ingress

Drying shrinkage

Reduction in permeability

Improved pumpability

|

|  |

|