Section1: IDENTIFICATION OF THE SUBSTANCE AND COMPANY

Product Name : MICROSILICA(SILICA FUME)

Manufacturer and contact : WATAD ALKHALIJIA TRADING CO .Limited Liability Company S.A. JCAA8970 SAUDI ARABIA – JEDDAH – NOJOD CENTER

Tel: +966 12 6655040

Info@watad-k.com

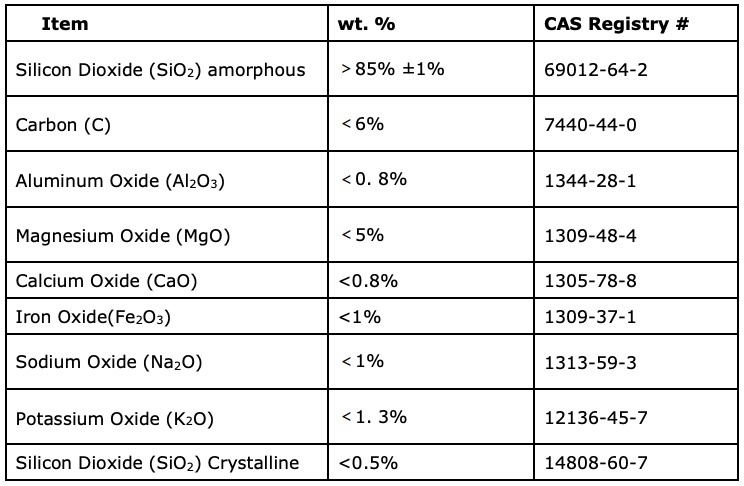

Section 2: COMPOSITION/INFORMATION ON INGREDIENTS

Above is Elemental analysis of the fume. The manufacturer can provide a more detailed analysis, including other trace elements.

Section 3: HAZARDS IDENTIFICATION

Microsilica is of low toxicity. Handling of Microsilica does not represent a health risk when usual safety rules are observed. Microsilica is generally considered to be a nuisance dust. High dust concentrations may cause irritation. Microsilica is unlikely to cause harmful effect when handled and stored as advised. Microsilica may contain trace amounts (<0.5%) of crystalline silica which has been shown to cause silicosis, and has been identified by IARC and NTP as a possible human carcinogen.

Section 4: FIRST AID MEASURES

INHALATION : Remove exposed person from dusty area to fresh air.

SKIN CONTACT : Wash skin with water and/or a mild detergent. Moisturizing cream or lotion may be applied to avoid skin dryness.

EYE CONTACT : Flush with water/saline solution to ensure no particles remain in eye. See a physician on persistent feeling of discomfort.

INGESTION : Not applicable

Section 5: FIRE FIGHTING MEASURES

Microsilica is not combustible and the dust presents no danger of explosion.

Extinguishing media: Not applicable (if involved in fire: cool with water).

Section 6: ACCIDENTAL RELEASE MEASURES

Contain spills or leaks. Transfer spilled material into an appropriate container. Collect spilled material using a vacuum cleaner or wash down with water. Do not use compressed air to maneuver dried material. Avoid generation of airborne dust.

Section 7: HANDLING AND STORAGE

HANDLING: Avoid handling that generates airborne dust.

STORAGE: Store in closed containers. Store away form hydrofluoric acid and fluorides.

Section 8: EXPOSURE CONTROLS/PERSONAL PROTECTION

Eye protection, eye flushing facilities and protective gloves are recommended. Ensure adequate ventilation. Wear an appropriate particulate respirator in accordance with 29 CFR 1910.134 or CSA Standard Z94.4-M1982 for dust exposure that may exceed exposure limits. If adequate ventilation is not possible, a self contained breathing apparatus or an air supplied respirator is recommended.

Section 9: PHYSICAL AND CHEMICAL PROPERTIES

Physical State : Ultrafine amorphous powder (respirable dust), dust forms agglomerates

Color : Light to dark gray

Odor : Odorless

Solubility (Water) : Insoluble to slightly soluble

Melting Point (°C) : Approx. 1230

Solubility (Organic solvents) : Insoluble to slightly soluble

Specific Gravity (water=1) : 2.2-2.3

Particle size (μm) : Approx 0.3

Section 10: STABILITY AND REACTIVITY

STABILITY : Microsilica is stable and does not react with water

MATERIALS TO AVOID : Avoid contact with hydrofluoric acid and fluorides

HAZARDOUS REACTIONS : Microsilica reacts with hydrofluoric acid (HF) forming toxic gas (SiF4)

HAZARDOUS DECOMPOSITION PRODUCTS : Prolonged heating above 500°C (930°F) will convert amorphous silica to the crystalline phases.

Section 11: TOXICOLOGICAL INFORMATION

ACUTE EFFECTS:

INGESTION : Dust from Microsilica may irritate and dehydrate mucous membranes.

INHALATION : Dust from Microsilica may irritate and dehydrate mucous membranes.

SKIN CONTACT : Dust from Microsilica may cause irritation and dehydration.

EYE CONTACT : Dust from Microsilica may cause irritation and dehydration.

CHRONIC EFFECTS:

Microsilica dust may contain impurities of crystalline quartz (<0.5%). Inhalation of Microsilica dust is considered to entail minimal risk of pulmonary fibrosis (silicosis). Cases of lung fibrosis have been reported among workers exposed to amorphous silica in the ferrosilicon industry. The lung changes have either been transient or may have been caused by simultaneous exposure to crystalline silica (quartz). Heating Microsilica above 500°C can result in the formation of crystalline SiO2-modifications (Cristobalite/Tridymite) which may cause silicosis. The formation rate increases with increasing temperature. Periodic health examinations of persons exposed to the dust are recommended to include: pulmonary examination, spirometry and possibly x-ray.

Section 12: ECOLOGICAL INFORMATION

Microsilica is not characterized as dangerous for the environment.

Section 13: DISPOSAL CONSIDERATIONS

Reuse all product when possible. Dispose of waste Microsilica according to applicable federal, state and local rules for non-hazardous solid waste materials. No special precautions are necessary during repacking. Microsilica is not a listed RCRA Hazardous Wastes (40CFR 261).

Section 14: TRANSPORT INFORMATION

DOT (DEPARTMENT OF TRANSPORTATION)

Proper Shipping Name : Not regulated

Hazard Class : Not regulated

I.D. Number and Initials : Not regulated

Packing Group : Not regulated

Label(s) : Not regulated

Section 15: REGULATORY INFORMATION

OSHA – Hazardous by definition of hazardous communication standard (29 CFR 1910.1200) TSCA (Toxic Substance Control Act): Components of this product are listed on the TSCA Inventory CERCLA (Comprehensive Response Compensation, and Liability Act): Micrsilica is not listed in 40 CFR 302.4 RCRA (Resource Conservation/Recovery Act): Microsilica is not a listed hazardous waste. SARA TITLE III (Superfund Amendments and Reauthorization Act): 311/312 Hazard Categories: Immediate Health, Delayed Health. 313 Reportable Ingredients: None. CALIFORNIA PROPOSITION 65: This product contains chemical(s) known to the State of California to cause cancer: Silica, crystalline

Section 16: OTHER INFORMATION

APPLICATION OF MICROSILICA: For use in refractory compositions, concrete and other systems containing hydraulic cement. Literature references are available upon request from the manufacturer.

The information above is believed to be accurate and represents the best information currently available to us. However, we make no warranty of merchantability or any other warranty, express or implied, with respect to such information, and we assume no liability resulting from its use. Users should make their own investigations to determine the suitability of the information for their particular purposes.

***End of MSDS***

|

|  |

|