Product Description

Cemex Falcons’ Ground Granulated Blast-furnace Slag “CEMEX GGBS” is a finely ground, powder-like Supplementary Cementitious Material (SCM). The raw material is called Granulated Blast-furnace Slag (GBFS), an industrial byproduct of iron and steel-making, recovered and recycled for its beneficial use, especially in the durability aspect of concrete. GGBS is considered one of the most sustainable construction material, as it is produced from a recovered industrial byproduct. Thus, reducing CO2 footprint and meeting LEED requirements. CEMEX GGBS is manufactured in Cemex Falcon LLC plant in Jebel Ali, Dubai UAE, by simultaneous drying and grinding of 100% GBFS in a vertical mill, under a strict ISO 9001 system and following CEMEX’s international production and quality standards. The raw material GBFS is guaranteed and secured from the world’s best available sources and the finished product is tested in Cemex’s stateof-the-art quality control laboratory ensuring compliance with standard requirements of BS EN 15167 & ASTM C989.

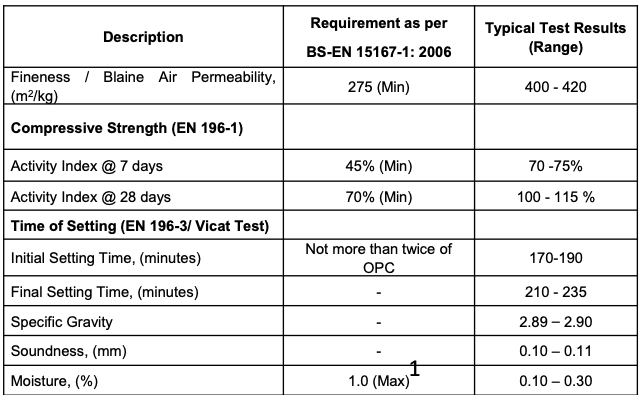

Physical Properties

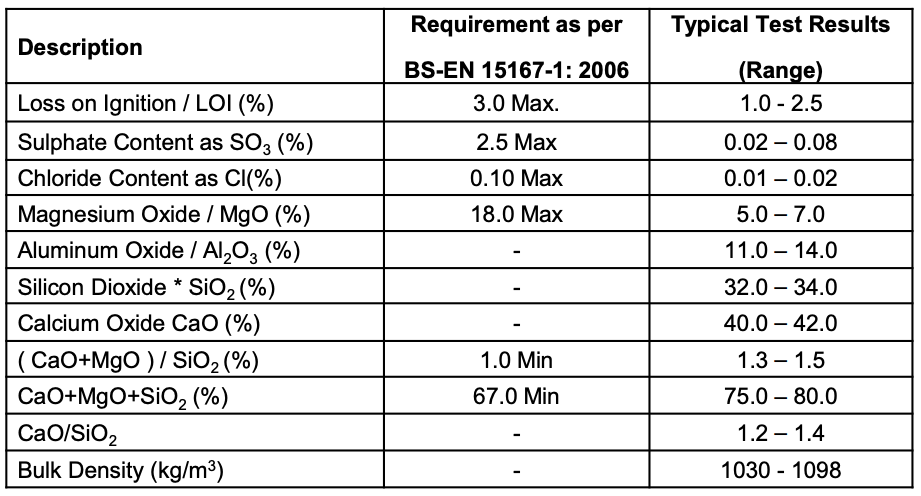

Chemical Composition

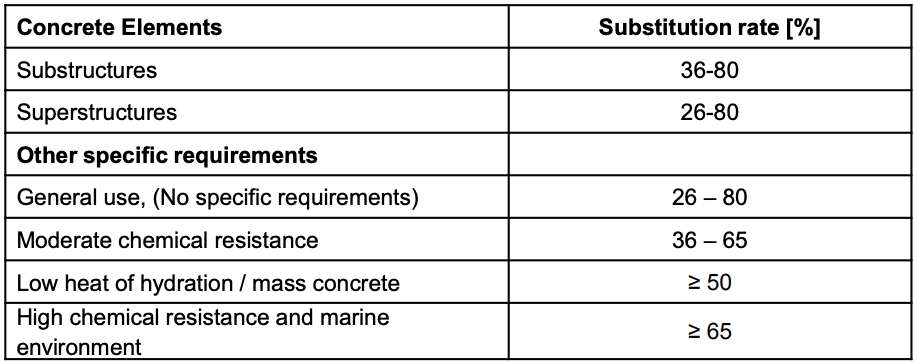

Recommended Substitution rates

In accordance with Dubai Municipality Circular # 225, following substitution rates are recommended:

Recommended substitution rates may vary depending on required concrete grade, cementitious content & Water/Binder ratio

Applications & Usage

▪ For general purpose

▪ Enhancing Concrete Durability

o Concrete structures, elements, foundations & pavements exposed to harsh environments

▪ Self-Compacting / Self-Consolidating Concrete

o Structures to be poured having congested reinforcements & limited access for compaction.

• Reducing Heat of Hydration/Thermal Stress

o Mass concrete

Note: Normally, concrete containing GGBS is expected to provide a minimal delay of Ultimate Compressive and Flexural Strength development compared with pure OPC. Slightly sacrificing the strength gained at early stage while giving importance for a higher strength after 90 days and beyond. If higher early strength is desired, mix design optimization is recommended. The use of appropriate accelerating admixtures is also an option, provided that all parameters shall be compliant with project requirements. As with all concrete mixtures, trial batches should be performed to verify concrete properties.

Advantages & Benefits

• Increases service life of concrete and decreases life cycle cost.

• Optimizes design of structural elements. Greater ability to handle unexpected increase of loads.

• Reduces water demand. Improves workability.

• Reduces permeability for greater resistance against penetration of chloride ions and sulfate attack

• Increases Abrasion & Chemical resistance for long-term durability and lower maintenance cost

• Increase resistance to shrinkage cracking.

• Mitigates Alkali-Silica Reaction (ASR)

• Improves consolidation and reduces concrete bleeding.

• Green & Environment-friendly

Admixture

Appropriate admixtures can be applied to extend special properties of CEMEX GGBS. Trial mixes shall be conducted to ascertain its’ compatibility, addition rate and maximum dosage.

Concrete Applications

Mixing

Batching and mixing of concrete containing GGBS is similar with pure OPC concrete. It is recommended that slag cement be batched following OPC proper procedure and with the same weighing apparatus and equipment.

Transporting

The concrete shall be transported to the site with an approved truck mixer or agitator truck. Periodic inspection inside the mixer should be conducted to ensure no concrete build-up that will impair the efficiency of mixing performance.

Placing

Concrete shall be placed to its final position before initial setting has started and shall not be successively disturbed. In many types of construction, concrete is placed into the forms and then consolidated by means of compaction. Consolidation densifies concrete within the forms, around reinforcements and embedded items. Proper compaction is usually conducted to avoid honeycomb and entrapped air.

Finishing

To produce a desired surface appearance, finishing operation should be carefully planned. It should be conducted on a proper timing considering weather condition and concreter setting time. Follow standard procedures on concrete finishing using appropriate tools and equipment.

Curing

As to all concrete, proper curing is essential to achieve the desired concrete properties. Typical concrete curing practice allows a minimum of 7 days curing period. Maintaining concrete in a moist condition using water sprinklers or spray, covered with wet burlap and/or polyethylene sheets, curing compounds coating and other water retaining techniques.

Storage and Handling

CEMEX GGBS shall be stored in an air-tight, water-proof silos, or in any manner to protect the material from moisture and contamination. Upon storage and handling, care should be taken to distinguish one material from the other. All handling equipment suitable for use with OPC & other types of cementitious materials is suitable for use on this product.

Availability

In bulk & Jumbo bags Disclaimer: Nothing comprised herein shall be considered or construed as a warranty or guaranty, either expressed or implied including any warranty of fitness for a particular purpose.

|

|  |

|